able to install the rotary table (A axis) for sparking, combined with sparking, automatically to rotate the table while machining [Option]

1. High speed MOSFET driven machining circuit for fast machining and high, medium, and low voltage options. Ideal for fine hole (with reduced copper tube wastes) and special substance machining.

2. Micro-computer based control system.

3. Intelligent deep hole machining. Simply enter desired machining current and all other machining parameters are set automatically.

4. Parameter changes during machining.

5. Power failure memory can last for 10 years.

6. Auto rotate release of workpiece after machining is completed.

7. X and Y axis optical scale with resolution up to 0.005mm and Z-axis decoder.

8. Auto Z-axis reset for machining re-counting.

9. Machining depth and coordinates display switch.

10. Capable of machining super hard alloy metal in irregular, sphere, and curve shapes.

11. Machining copper tube of diameter above 0.21mm with pure water for better safety while those of diameter between 0.008 and 0.2mm are machined with EDM oil for more precise hole diameter.

OPTIONS:

4 th axis (Z2 axis)

Z2 axis for machining different height (OPT).

|

ER collet chuck: Ø0.3~Ø6.35mm.(OPT)

|

Standard: Electrove Ø1.0 x 1pc/ Guode Ø1.0mm x 10pc.

|

|

Precision chuck: Ø0.1~Ø3mm.(standard)

|

Fillter: Standard

|

| ITEM \ MODEL |

UNIT |

SD350 |

SD350 |

SD400 |

SD450 |

SD550 |

SD600 |

SD755 |

| Work table (L x W) |

mm

inch |

460x120

(18.1x8.3) |

600×300

23.6×11.8 |

600×300

23.6×11.8 |

600×300

23.6×11.8 |

800×450

31.5×17.7 |

800×450

31.5×17.7 |

1100x600

(43x24) |

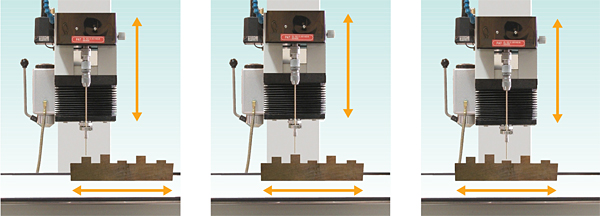

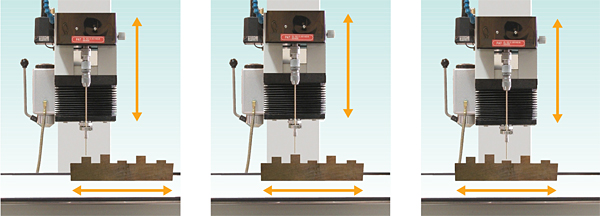

| Table travel (X) |

mm/inch |

300(11.8) |

350(13.8) |

400(15.7) |

450(17.7) |

550(21.7) |

600(23.6) |

750(29.5) |

| Table travel (Y) |

mm/inch |

200(7.9) |

300(11.8) |

300(11.8) |

350(13.8) |

400(15.7) |

400(15.7) |

500(15.7) |

| Spindle servo travel (Z1) |

mm/inch |

345(13.6) |

| W axis travel (Z2) |

mm/inch |

NA |

200(7.9) |

200(7.9) |

200(7.9) |

250(9.8) |

250(9.8) |

370(14.6) |

| Electrode guide travel (Z3) |

mm/inch |

150(5.9) |

| Working fluid tank capacity |

L |

20L 純水 |

| Max. workpiece weight |

KGS. |

100 |

150 |

180 |

180 |

400 |

450 |

750 |

| Machine weight (net) |

KGS. |

700 |

1000 |

1200 |

1350 |

1950 |

2100 |

2950 |

| Power source |

V |

220/380/415/440 |

| Max. power consumption |

KVA |

4.5 |

| Max. machining current |

A |

50 |

All specifications and designs are subject to change without notice.

Larger models are avallable as requests.

STANDARD ACCESSORIES :

| Paper |

1 Pc |

| Tool box |

1 Set |

| Electrode guide Ø1.0mm |

1 Pc |

| Precision electrode holder Ø0mm-Ø3mm |

1 Pc |

| Electrode tube Ø1.0mm |

10 Pcs |

| Halogen work lamp |

1 Pc |

| X, T, Z-axes digitel readout & encoder |

1 Set |

| Levelling pad |

1 Set |

| X, Y, Z-axes ball screw (SD350, 400, 550, 640) |

1 Set |

OPTIONAL ACCESSORIES:

- Electrode guide.

- Elctrode tube.

- ER type precision collect holder, capacity up to Ø6.35mm.

- 4th axis (Z2 axis) (For CNC series)

- Filter